ASUS NUC Extreme: Tough and Ready for Business

Each NUC unit is subjected to extensive and rigorous testing to ensure it can withstand the wear and tear of constant use as well as the harshest environments. Designed to exceed industry standards, the meticulous ASUS testing process guarantees each product delivers outstanding durability and performance. This unwavering commitment to excellence ensures that ASUS NUC offerings deliver exceptional reliability to provide customers with a powerful and long-lasting solution designed to perform seamlessly, day after day.

Extraordinary Reliability, Global Support

With an impressively low return rate of just 1%, ASUS NUC delivers the reliability that you can trust. Designed for quality beyond expectations, it ensures smooth business operations while lowering total cost of ownership (TCO).

ASUS NUC products are built to deliver consistent performance from day one, ensuring smooth operations and long-term value for your business.

ASUS provides local service and support in 84 countries, ensuring reliable technical assistance whenever you need it.

ASUS NUC is the result of superior manufacturing, advanced design, and comprehensive military-grade reliability. Each unit is subjected to nine specific tests to ensure reliable performance in the harshest conditions.

High-Temperature Test

Duration: 7 days (7 x 24-hour cycle)

Temperature: 33 to 71° C

Unit is non-operational during test

&

Duration: 3 days (3 x 24-hour cycle)

Temperature: 32 to 49° C cycling temperature exposure

Unit is operational during test

Low-Temperature Test

Duration: 7 days (7 x 24-hour cycle)

Temperature: -25 to -33° C

Unit is non-operational during test

&

Duration: 3 days (3 x 24-hour cycle)

Temperature: -21 to -32° C

Unit is operational during test

Altitude Test

Duration: 12 hours

Temperature: -20° C

Unit is non-operational during test

&

Duration: 12 hours

Temperature: 5° C and 40° C

Unit is operational during test

Humidity Test

Duration: 10 days (10 x 24-hour cycle)

Temperature: 30° C and 60° C

Humidity: 95% relative humidity (RH) (constant)

Unit is non-operational during test

Shock Test

Drop height: 100 mm

Unit is operational during test

Vibration Test

Test time: 40 min/axis

Unit is non-operational during test

* The testing regime meets the requirements of both military-grade standards and ASUS quality tests, and varies depending on device. MIL-STD-810 testing is conducted on select ASUS products only. Note that the MIL-STD-810 testing helps to ensure the quality of ASUS products but does not indicate a particular fitness for military use. Tests are performed under laboratory conditions. Any damage caused by attempts to replicate these test conditions would be considered accidental, and would not be covered by the standard ASUS warranty. Additional coverage is available with ASUS Premium Care.

ASUS NUC : Tested for Perfection

Cross Section

Solder joints are checked to ensure they meet IPC-A-610 certification standards.

Temperature Shock

This test ensures that the solder joints will hold up over the product life cycle.

> 600 cycles, -40 to 100° C

Drop test

Products are dropped from a height of 80cm, with one drop across all six faces, three edges, and two corners.

Port Test

1500-cycle insertion-and-removal tests help ensure connector durability, functionality, and structural integrity.

Package Bump Test

Products are subjected to 4000 bumps to test the ability to withstand even the harshest shipping conditions.

Package Drop Test

This test ensures that the product is well-protected during transport and shipping.

Noise & Audio Test

Products are tested to ensure system noise levels do not exceed ISO 7779 requirements.

Thermal Bake Test

This test ensures that the thermal solution holds up to long-term exposure to high temperatures.

Package Vibration Test

This test ensures that the packaging protects the product from vibrations.

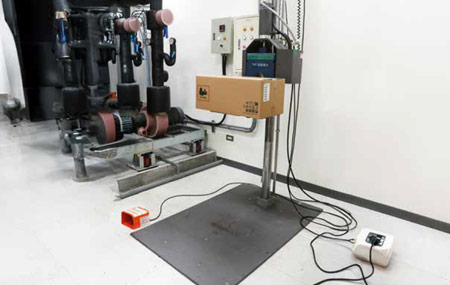

Mean time between failures (MTBF)

Our unwavering commitment to quality is demonstrated through rigorous reliability testing, showcasing an MTBF of over 50,000 hours. Unlike typical estimated MTBF, we go beyond the industry standard by placing forty NUC units in a chamber and exposing them to 40°C temperature for 90 days. This hands-on approach guarantees 24/7 reliable operation and provides long-term assurance for our valued customers.

*All tests are interrelated, and the sequence or content may be adjusted based on the specific requirements of the project